Textile Exchange has published a comprehensive report, “The Future of Synthetics”, which shows a roadmap towards a more sustainable future for synthetic fibres in the textile industry.

Below is a closer look at the key findings and suggested actions.

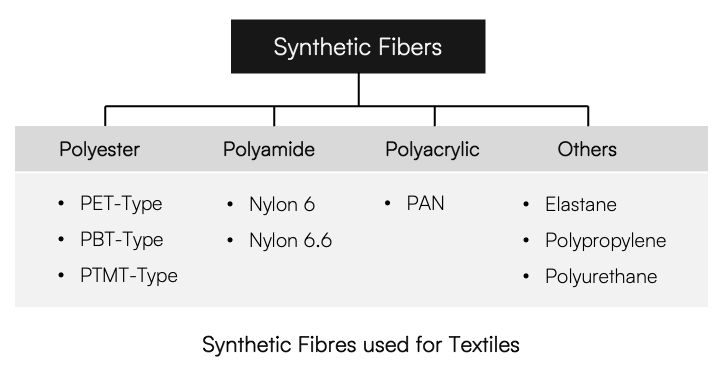

Synthetic fibres make up more than 60% of the volume of all textile fibres used in a range of commercial products such as apparel, home textile, and footwear. They are also commonly used in other sectors like technical textiles for healthcare, automotive, and aeroplanes.

Among different types of synthetic fibres, polyester is the most widely produced fibres making up 54% of the global market in 2022.

All synthetic fibres are made through chemical processes using fossil fuel-based inputs like petrochemicals, making them inherently unsustainable. The production process requires a substantial amount of energy and exacerbates a myriad of environmental issues, such as water pollution and greenhouse gas emissions, which contribute to climate change. In addition, all synthetic fibres cannot be completely broken down by microorganisms. Therefore, microfibres accumulate in the environment for long periods, such as in riverbeds and beaches.

What are the key areas where we can reduce the negative impact of synthetic fibres?

The two most important measures to reduce the negative impacts of synthetic fibres are:

- Eliminate new and virgin fossil fuels as feedstock

- Reduce the volume of new materials and products produced overall

The Future of Synthetics report gives three Key Findings on how to reduce the environmental impact of synthetic fibres

- Textile-to-Textile Recycling

Almost all recycled polyester for the textile industry comes from mechanically recycled PET bottles. However, the current way of using PET bottles to produce recycled polyester fibres has disadvantages: it disrupts the established cradle-to-cradle system for PETs plastic bottles, changing the cycle into a linear, environmentally unsustainable “take-use-dispose” pattern.

Therefore, the need to find alternatives to PET bottles is pressing. This will also mean prioritising the development of textile-to-textile feedstocks at scale. Although an infrastructure for textile-to-textile recycling systems is yet to be established, there are already promising new chemical recycling technologies that can be used mainly for polyester and fibred blends. Polyamide recycling is still a challenge because the two primary types, Nylon 6 and Nylon 6.6, must be separated for recycling.

- Biosynthetics

Biosynthetics are fibres that are partially or fully made from biobased and renewable feedstock like starch, sugar, vegetable oils or proteins. Although biosynthetics are already available, most of them are not made by using fully biobased content and still require petroleum-based additives to make the material performance robust enough for textile applications.

The market share of biobased synthetic fibres is still very low due to the high price point and questions about the sustainability of currently available biobased materials. Further research and development for processing and manufacturing are needed to make these materials more commercially available.

- Carbon Capture

Using CO2 emissions as a feedstock in place of virgin fossil fuels is an emerging area of interest across industries. Textile innovators are taking this one step further by developing an “emission-to-textile” process where textiles are produced using waste methane and CO2 emissions from the atmosphere.

There are different technologies that currently exist and are being developed with this concept in mind, called “carbon capture”. During the carbon capture process, waste carbon emissions are captured and CO2 is separated through various methods. Once the CO2 is isolated, it gets compressed and stored in liquid form for transport. The CO2 is then processed to convert into chemicals used in synthetic textiles, such as polyester. Although there are still challenges in developing and implementing carbon capture technologies, they hold the potential to enable the textile industry to achieve its impact goals towards a more sustainable future.

Although a total shift away from synthetic materials is not currently possible, it is necessary to find ways to repurpose existing synthetic textile wastes and reduce the amount of new fossil fuel-based materials.

Follow our LinkedIn page and check out our news channel to learn more about our sustainability initiatives and business updates.